Sample Tutorial

Lead Through Teaching with Teach Pendant:

|

Note:

Hyperlinks will work when it is viewed from the tutorial system.

|

Advantages

of lead through teaching vs. importing scanned images.

1- Not restricted

to drawings or pictures that will fit on a scanner bed.

2- No need

to task swap between programs to correctly format data.

3- Quickly

and easily program complex or geometric forms.

4- Allows programing

of original artwork in any size desired.

5- Easily reproduce

existing artwork or part forms.

6- Very short

learning curve, no previous programming experience required!

7- Maximize

material utilization.

Lead Through Teaching:

To begin, Connect the teach

pendant to the DB-15 connector on the back of the controller.

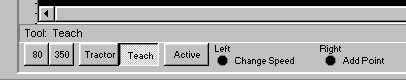

Click on the teach button "T"

on the side tool bar in the software.

Set your jog

speeds by left clicking on the appropriate button on the bottom

of the screen and then entering the value you want. Click OK.

A slow speed of 10 and a high speed

of 125 work very well for most applications.

The left button on the teach pendant

is the speed change button. Pushing this button will toggle between the

two selected speeds.

Click the "ACTIVE" button

on the bottom of the screen. The pendant is now active.

The right button on the teach pendant

adds a new point to the G-code. Pressing

this button will write the current torch position to the next line in code.

If desired, press <CTRL-P>

to bring up the D.R.O. display window.

This brings up a large digital read out window to display the current X

and Y positions. This will allow you to read the exact torch position while

using the teach pendant.

Moving the joystick

will jog the machine at the set jog speed. Push the left teach pendant

button to toggle between the set speeds.

Position the torch over the pattern

you are tracing and press the right button for each new point you want

to add. You can tape a scribe or other pointing device to the torch or

use our optional laser pointer for

more precise positioning.

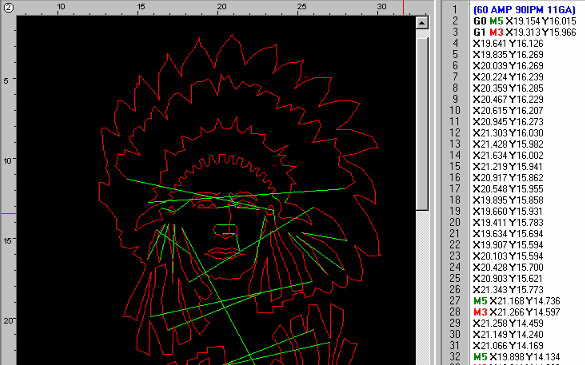

Take a minute to look over the part

you are tracing and determine cut order and start and end points. It is

generally best to cut the interior features first and move on to the outer

perimeter last. This helps prevent the material from moving during the

cutting process. You can also program your lead

in/out points during lead through teaching. As each successive

point is added it will show on the screen.

After you have taught all positions,

save the file. <CTRL-S>

Turn off the D.R.O. display. <CTRL-P>

and bring up the G-code editor screen.

<CTRL-E>

Left click the editor window to

place the cursor on any line and scroll up to line number one. You will

notice as you scroll up and down the list in the editor window that the

crosshair in the main screen window

follows the coordinates in the G-code editor.

You can now set the tool

path speeds and torch on/off commands

to your G-code. |